The Swine Health Information Center funded a project to generate a data-driven swine disease index through monitoring swine pathogen activity using confirmed tissue-based diagnoses from Iowa State University Veterinary Diagnostic Laboratory. This initiative aimed to provide a transparent, automated, and reproducible method to help veterinarians, producers, and stakeholders prioritize disease threats based on real-world diagnostic data. Led by PhD Candidate Guilherme Cezar under the supervision of principal investigators Drs. Giovani Trevisan and Daniel Linhares, the resulting disease index monitors swine pathogen activity and identifies emerging threats. In addition, the index can be adapted and integrated into the SHIC-funded Swine Disease Reporting System for continuous monitoring.

Find the industry summary for Swine Health Information Center project #24-016 here.

To build the swine disease index, 59,950 ISU-VDL porcine cases from 2020 to 2024 were utilized. Four key factors were considered:

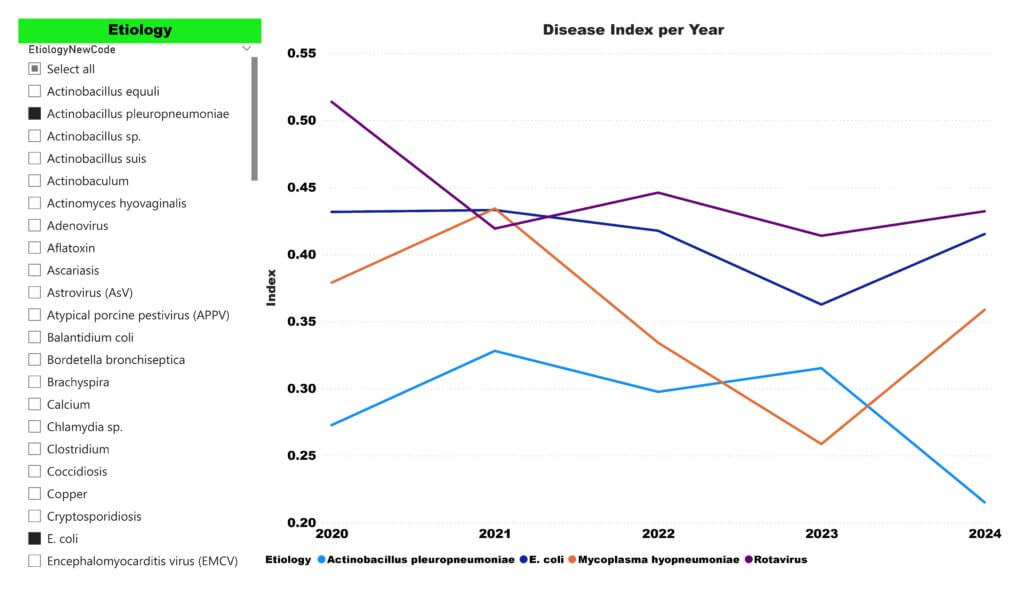

These factors were weighted and combined into a single score for each disease, updated weekly for the ongoing year, and displayed in an interactive Power BI dashboard that will be housed on the SDRS website. Investigators anticipate the Power BI Dashboard will be available in early 2026 and will display annual disease index data. The dataset used was annotated by diagnostic codes, farm type, geographical data, and accession IDs. Four normalized variables were used to build the index: disease occurrence, co-diagnoses, geographic spread, and Early Aberration Reporting System (EARS) alarms. These measures were weighted using an R-based function and combined into a single scale ranging from 0.01 to 1. Statistical validation—using resampling, Euclidean, and Manhattan distance models—ensured robust consistency across years.

Results confirmed that PRRSV and Streptococcus suis remain the top two-ranked pathogens, demonstrating their high activity in the US swine industry. The system also detected emerging pathogens’ activity in 2024, including porcine sapovirus and porcine astrovirus, while PCV2 showed a notable decline. The dashboard allows users to track disease trends and compare rankings year-to-year, supporting real time decision-making. The index was validated using modeling to assess year-to-year consistency and detect emerging or declining disease trends. Bootstrap resampling (500 iterations) generated 95% confidence intervals for index predictions, excluding EARS due to model limitations. The interactive Power BI dashboard provides real-time visualization and weekly index updates which can be monitored by the SDRS team, and ongoing changes communicated to the industryKey findings revealed high stability in pathogen indexes across years, with a Spearman correlation of 0.92. PRRSV and Streptococcus suis consistently ranked as top burdens, underscoring their persistent importance. However, the method also registered new priorities: porcine sapovirus and astrovirus after they had an increased number of cases in 2022 and 2023, respectively, emerged as more significant endemic pathogens. In contrast, PCV2, traditionally considered a dominant pathogen, fell out of the top 10 by 2024. This decline may reflect improved herd immunity, vaccination, or biosecurity interventions.

Although infectious diseases dominated the rankings, the system also captured nutritional and toxicological diagnoses, which—while less common—introduce diversity to the surveillance profile. Their variability and occasional abrupt ranking shifts highlight the utility of keeping such categories under close observation for early detection of non-infectious threats.

The disease index’s strength lies not only in its reproducibility but also in its adaptability. Its integration into a Power BI dashboard monitored internally by SDRS staff provides a real-time, visually accessible tool, updated weekly, that supports veterinarians, producers, and industry stakeholders in quickly identifying emerging disease threats and allocating resources efficiently. By combining multifactorial epidemiological variables rather than relying on occurrence alone, the index captures both pathogen prevalence and broader dynamics such as geographic spread and co-disease patterns.

Overall, the index presents a scalable and transparent foundation for swine disease prioritization, enabling continuous, longitudinal monitoring that differentiates between stable endemic pathogens and volatile or emerging threats. Its validation across multiple statistical models ensures consistency while maintaining sensitivity to dynamic changes. Moving forward, investigators recommend integrating the framework into SDRS, refining weighting algorithms, and considering extension of the concept to other livestock systems to further enhance animal health security. By combining epidemiological rigor with automated analytics, this study delivers a timely and flexible tool that strengthens swine health surveillance and informs science-based disease control strategies.

The Swine Health Information Center, launched in 2015 with Pork Checkoff funding, protects and enhances the health of the US swine herd by minimizing the impact of emerging disease threats through preparedness, coordinated communications, global disease monitoring, analysis of swine health data, and targeted research investments. As a conduit of information and research, SHIC encourages sharing of its publications and research. Forward, reprint, and quote SHIC material freely. For more information, visit http://www.swinehealth.org or contact Dr. Megan Niederwerder at [email protected] or Dr. Lisa Becton at [email protected].